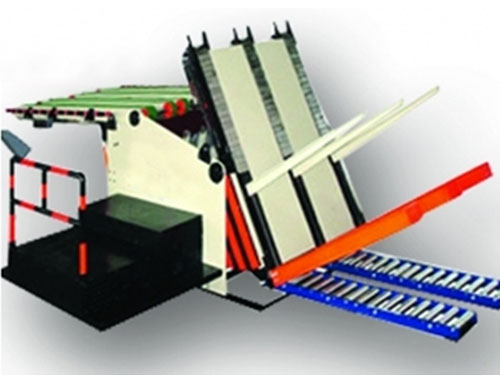

good quality good price high speed ink printing slotting mach

The authors:SHANGHAI SHUNGE Release time:2015-07-17

good quality good price high speed ink printing slotting machine carton machinery factory:One, the whole machine features:1) the machine by paper, printing, slitting, accumulation and other parts, can be a complete three, five, seven layers

good quality good price high speed ink printing slotting machine

carton machinery factory:One, the whole machine features:

1) the machine by paper, printing, slitting, accumulation and other parts, can be a complete three, five, seven layers of corrugated cardboard printing, pressure, slotting and Angle cutting process;

2) transmission system all adopt the big spiral Angle of oblique gear transmission, low noise, enhance the strength of gear, improved the gear transmission stability.All 20 crmnti drive gear adopt high quality alloy steel, fine grinding, superhard processing, enclosed spray lubrication;

3) all bearing adopts "axis" and "wazhou" and other famous brand bearing;

4) each unit on-off electric with alarm, clutch last warning bell ring, ensure the safety of the workers.With constant torque clutch, clutch motor can buffer error operating units collided with each other;

5) after the unit fold, pneumatic locking between each group, and is equipped with a total locking cylinder, can make various units and the bottom rail locking one integrated mass.Cylinder is not locked, main motor cannot be started;The main motor running, unable to open lock cylinder.Automatic braking units after the separation of transmission system, keep the original gear fixed position;

6) units all have automatic zero system, try to send a small board can be adjusted to the correct size, reduce the waste board;

7) printing and slotting phase adjustment adopts electric digital input type, in work or stop state can be adjusted by 360 degrees, otherwise clean version of the memory and automatic zero system.Adjustable axial adjustment for manual, distance of 20 mm;

8) overall modelling beauty, color soft.Modular design to make you any increase or decrease in the unit.

Second, the main technical parameters

1) the highest printing speed: 100 / minute;

2) economic printing speed: 80 / minute;

3) the greater than paper size: 1300 * 2400 mm;

4) minimum paper size: 330 x 500 mm (full version);

5) effective printing size: 1300 * 2200 mm;

6) accuracy: + / - 0.75 mm or less;

7) slot accuracy: + / - 1.6 mm or less

Three, the main organization performance

(a) paper department:

1) the suction automatic feeding system, wind strength and suction width adjustable;

2) brush dust removal device and equipped with dust collection fan, can remove the dust on the surface of the board by a large number of;

3) the rocker slider built-in double pure rolling bearing structure design, can reduce wear eliminate clearance;

4) push board for aluminum alloy material, low auxiliary protection department is equipped with rolling bearings, can withstand heavy cardboard deformation;

5) on paper board manual adjustment, side platens electricity;

6) groove glue roller composite paper, pneumatic buffer device is designed sending paper roller, to adapt to changes in the thickness of the cardboard, and to avoid damage to the machine when the piece of cardboard into more;

7) can be set planned production quantity.Computer system automatically complete the plan instruction to stop feeding and issued a warning signal.

(2) printing department:

1) printing roller surface grinding hard chromium plating polishing correction of balance;

2) the embossing roller adopts double plate welding, hard chrome plating of dynamic and static balance correction surface;

3) rubber roller roller with high to compensate for the stress deformation and improve the effect of the ink, for the steel roller surface hard chromium plating, line 180-240 line/inch optional, rubber roller roller automatic cleaning system;

4) automatic cycle to the ink system of diaphragm pump, and add ink cup to prevent ink splash and exhaust stainless steel storage ink fountain;

5) the automatic ink device which can realize power constantly ink function;

6) pneumatic lifting net roller prevent plate repeat lis and short outage nets roller hole ink when dry;

(3) the slot department:

1) the upper and lower cutter and line pressing wheel up and down or so mobile synchronization manually adjust;

2) high box adjustment: slot synchronization manually adjust

The relevant information: