Automatic Flute laminating machine

> Brief Introduction

1. Our company manufacture professionally KTM series of Automatic Flute Laminator, The application of corrugated are A, B, C, D, E, F, N treng and three, five, seven story can work. The fluted paper is in good flatness and high accuracy

2. Well-known manufacturers of genuine products are adopted in the main parts of our machine, whice makes life, good stability. The world's well-known brands products are adopted in electrical parts, imported bearings is adopted in the key parts, to ensure the stability of the whole performance.

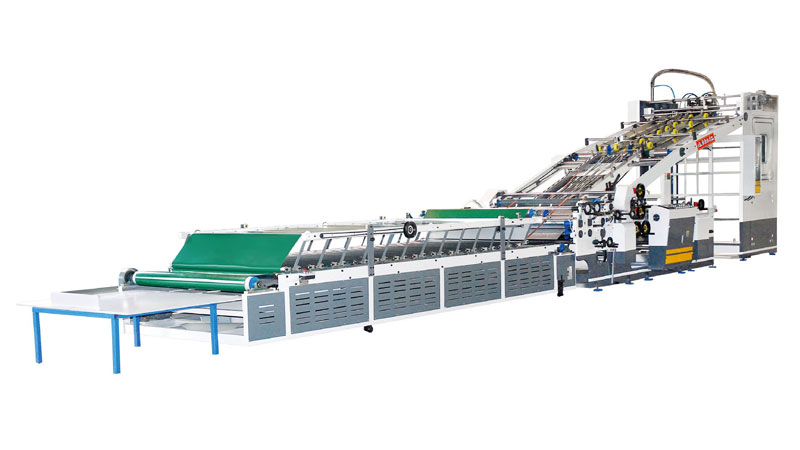

> Automatic Flute Laminator parts introduction

|

|

|

|

|

| Surface Paper Feeding Part The Feeding device ensures that the feeding of surface paper is smooth and accurate. |

Adjustment System Fine regulator completely manufactured in Japan is adopted, which actualizes the adjustment of pasting tolerance during the course of working with high speed,thus improving the working efficiency |

Alignment System Synchronous sheet pusher particularly designed ensures that the surface paper and bottom paper enter the pasting part at the same time. It can be fine adjusted during the course of working. |

Bottom Paper Conveying Part Synchronous sheet pusher particularly designed ensures the stable and accurate conveying of cardboards heavier than 300g/m2, and corrugated boards of A,B,C,D,E,F,N and three, five or seven layers. |

Surface Paper Conveying Part Unique central gear made of wear-resistant PU rubber cooperating with conveying belt ensures stability and smoothness of conveying, which is adaptive for different sheets of different thickness without any abrasion for the printing surface. |

|

|

|

|

|

| Driving System Imported wear-resistance timing belt, belt wheels cooperating with sheet pusher,adjustment system and alignment mechanism ensures a paste tolerance of ±1.5mm and reduction of torn sheet |

Adding Glue and Gumming System Automatic adding glue system detects by electrically operated fluid controller and adds gule automatically during the course of pasting. The thickness of glue is adjustable according to the paper. Recycling system of glue avoids a waste of glue and swinging glue, and ensures accurate and tidy laminating.Unique applied anilox roller glues evenly,even suitable for ardboards and cardboards. |

Bottom Paper Feeding Part Imported suction feeding device with punching belts ensures stable feeding at high speed. It is suitable for cardboard eavier than 300g/m2, corruggated boards of A,B,C,D,E,F,N and three, five or seven layers. |

Electrical Control Part All the electrical power adopted the worldrenowned brands, steady and dureable, frequency speed govering, lower noise and energy conservation. |

> Automatic Flute Laminator Specifications

| Model | KTM1300 |

KTM1450 |

| Max. paper size | 1300×1100 | 1450×1100 |

| Mini paper size | 400×400 | 400×400 |

| Min. basis weight of bottom paper | 350gsm | 350gsm |

| Max. basis weight | 800 | 800 |

| Max. thickness | 10 | 10 |

| Min. basis weight of face paper | 180 | 180 |

| Max. basis weight | 800 | 800 |

| Precision of paperboard and cardboard | ±1.2 | ±1.2 |

| Precision of paperboard and corrugated board | ±1.5 | ±1.5 |

| Machine speed | 100张/分 | 100张/分 |

| Total length | 12.5 | 12.5 |

| Total power | 15 | 15 |

| Total weight | 6.8 | 7.2 |

Contact us and Browse more related products news

Add: zhongmin road Maogang town, songjiang district, Shanghai

Mob:0086-13102721466

Website: http://www.cartonpackagingmachinery.com

Skype:hbdgzxjx

wechat:dgcartonmachine

WhatApp:+8613102721466

Email:shcartonmachine @163.com

Mob:0086-13102721466

Website: http://www.cartonpackagingmachinery.com

Skype:hbdgzxjx

wechat:dgcartonmachine

WhatApp:+8613102721466

Email:shcartonmachine @163.com

Automatic printing sticky and nail linkages

High speed ink printing adhesive box packaging linkage line

Full automatic high speed down folding boxlinkage line(light)

Full automatic high speed down folding boxlinkage line(heavy duty)

Touch line machines

Corrugated cardboard production line

Industrial cardboard production line

Single facer

Mill roll stand

Pre heater

Conveyer bridge

Gluing machine

Double facer

Cutting off machine

Slitter scorer

Stacker

Paper cutter

Flexo Printer Slotter Die Cutter Machine series

Slotter machine series

Thin blade machine

Slitter score machine

Flute laminating machine series

flat to flat Die-cutting&Creasing Machine Series

Rotary Die-Cutting Machine series

Die cutting machine

Carton folder gluer machine

Small box gluer machine

Foil-Stamping & Cutting Machine

Stitching Machine series

Automatic feeding machine

Taobao box(1-12)packer

Type a automatic double head packer

Automatic double head packer(c-type machine)pe

Binding machine

Partition Board Machine

Corrugated roller

Carton machine parts

The relevant information: