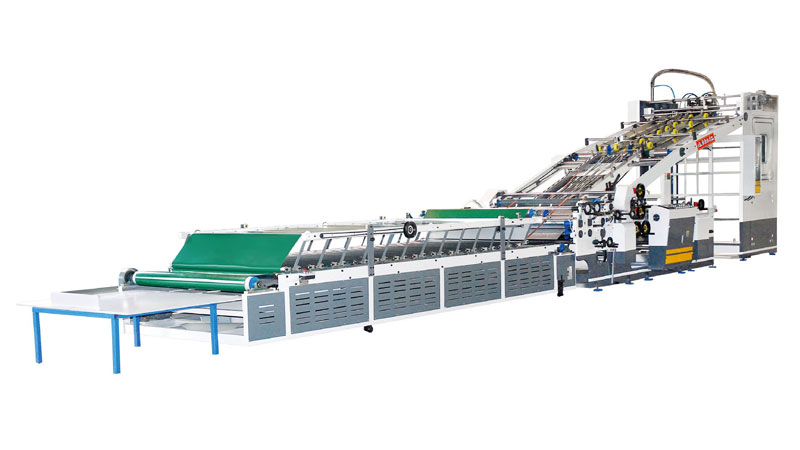

High speed lift laminating machine

Features

FMY series automatic laminating machine features a unique front extension spring design reduces the mechanical regulation failure rate, with the intelligent control to ensure accurate positioning fit. This machine adopts frequency control, PLC centralized control, analog-digital conversion, operation and precise control. Glue roller design in the high roller with knurled uniform coating greatly improved the uniformity, improved lamination strength, reduced customer production costs. Steel roll through balanced and tested to meet the tight assembly process to effectively improve the mechanical stability, combined with the main transmission using timing belt drive, direct suction bottom paper feed tray, effectively improve the mechanical accuracy and speed of operation. automatic level control system, laminating machine, automatic glue on the cycle, greatly reducing the labor intensity. Independently developed a strong feeder paper feeding device accompanied by the pre-code, reduce downtime, improve work efficiency. This machine is suitable for 200-450GSM glossy paper with A, B, C, D, E, F wave and three-and five cardboard (maximum thickness ≤ 8 mm) fit.

Technical parameters

| Model | FMY-1300 | FMY-1450 |

| Maximum paper size | 1300×1100mm | 1450×1100mm |

| Minimum paper weight | 350×350mm | 350×350mm |

| Maximum machine speed | 6000Sheet/h | 6000Sheet/h |

| Total Power | 12kw | 12kw |

| Lamination precision | ≤±1.5mm | ≤±1.5mm |

| Mechanical length | 12.5m | 12.5m |

| Machine weight | 6.8T | 7.2T |

Mob:0086-13102721466

Website: http://www.cartonpackagingmachinery.com

Skype:hbdgzxjx

wechat:dgcartonmachine

WhatApp:+8613102721466

Email:shcartonmachine @163.com